In the Southern Downs region, outside of Warwick, is a secret indoor facility for growing medicinal cannabis.

It rarely allows visitors, and until now, has not permitted media.

The nondescript building is surrounded by high fences, barbed wire, guard dogs and security doors.

It's one of the first cannabis flower farms in Queensland and Australia.

While thousands of Queenslanders have been using medicinal cannabis 'flower' since it was federally legalised in 2016, most people probably don't know 90 per cent of it is imported.

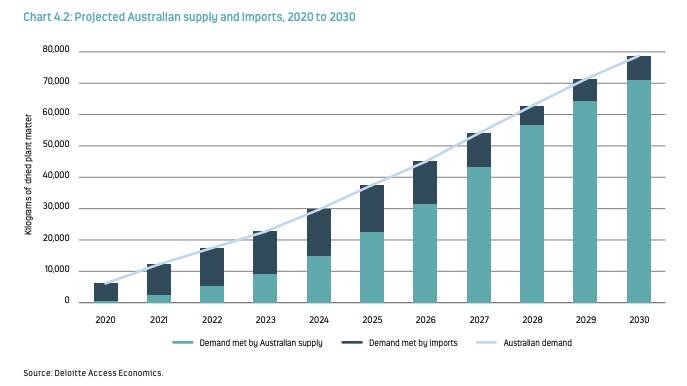

According to Deloitte, about 5.5 tonnes of the 6.1t consumed in Australia in 2020 came from overseas.

Incredibly, the proportion of total domestic demand serviced by imported medicinal cannabis is expected to fall to about 10 per cent in 2030.

Medicinal Harvest built the high tech site in 2020-21, began cultivation in June 2021 and dispatched the first of its finished product in October 2021.

Founders and owners Andrew Olley and Tracey Perez are playing a part in the country's transition from net importer to domestic powerhouse.

Mr Olley said as doctors, pharmacies and patients became more aware of where and how medicinal cannabis was grown, product traceability, sustainable production and Australian grown were valued by the supply chain.

"There is a supply chain preference for Australian produced flower bud due to traceability and certainty about zero pesticide use and the meeting of microbial standards," Mr Olley said.

"There is also a preference for product with strong sustainability credentials."

Domestic v imported

Oral liquid products have accounted for most medicinal approvals, however, the use of flower products has recently increased, with 33,831 approvals for dried flower products in 2021 alone, compared with just 167 during the previous year.

Since 2016, domestic manufacturers have had to meet the Therapeutic Goods Administration's good manufacturing practice standards.

However, imported products have not been required to comply.

Several industry stakeholders voiced concerns about this and it appears the TGA has listened, because from July 2023, all medicinal cannabis products supplied in Australia must be manufactured according to relevant GMP codes.

With commercial success behind them and a more certain future ahead, expansion is a key strategy for Medicinal Harvest over the coming 12 months.

It is planning two additional facilities at the existing location, with further expansion possible due to the large size of the property and the availability of water and energy.

"Earthworks have begun on the next facility and by the end of 2023 we expect to be producing three tonnes of flower bud per year," Mr Olley said.

Mr Olley is no blown-in looking to make a quick buck - he has an agricultural science degree specialising in plant nutrition and protected cropping.

He also has 25 years experience in all aspects of plant nutrition, greenhouse and hydroponic production techniques for a multitude of crops.

He is in charge of producing high THC flower bud that is on-sold by the TGA-licenced supply company that purchases its product.

Cannabis primarily contains the psychoactive cannabinoid, tetrahydrocannabinol, and the non-psychoactive cannabidiol.

The most common condition for which medicinal cannabis has been approved is chronic pain. It is also commonly approved for anxiety, sleep issues and cancer pain.

The facility is an indoor cultivation system with positive pressure air control, utilising high output LED lights in the flowering compartments.

There are multiple rooms for the different stages of cultivation and production, each with separate environmental controls via air conditioning, dehumidifiers, and UV filtering.

A nutrient film technique hydroponic growing system allows for clean growing conditions to be maintained and the optimisation of crop cycle times.

The facility implements a staggered crop planting with up to seven plant stages represented at any one time.

The facility has ready access to water and electricity, while also being highly water and energy efficient. Water from the NFT growing system and the facility atmosphere is recycled and an onsite solar farm provides 100pc of the facility's power during the day.

When additional water is required to enter the system, it is available from rainwater tanks or reverse osmosis of bore water.

From $30 million to $400m

Medicinal Harvest is part of a growing Australian medicinal cannabis market, with revenue from sales in 2021 estimated by Penington Institute to be at $230 million.

This number is expected to reach more than $400 million through 2022.

The value of this market has increased rapidly in just the past three years, increasing from $30 million in 2019.

Queensland has seen the rise of a number of large private 'cannabis clinics' in the state, which focus solely on medicinal cannabis treatment.

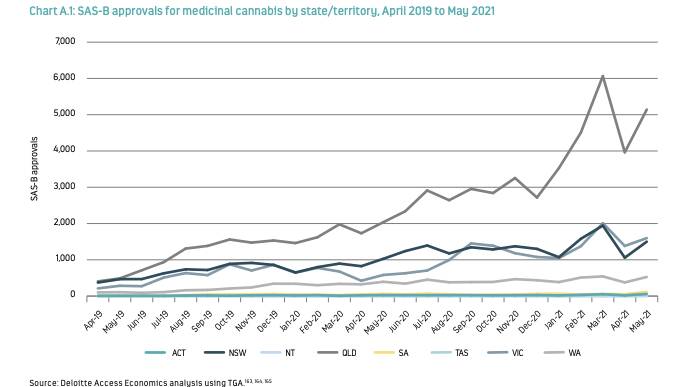

As a result, there have been far more 'SAS-B' applications for medicinal cannabis in Queensland than in other Australian jurisdictions.

In Queensland in 2021, 638 prescribers facilitated 67,952 approvals.

Since 2016, the TGA has given more than 250,000 approvals nationally under the SAS-B pathway, almost half of which were given in 2021.

Estimates of the number of medicinal cannabis patients in Australia are between 17,000 and 90,000.

The growth of the market does not appear to be slowing down, with Melbourne-based medicinal company Montu announced as the 2022 Deloitte Technology Fast 50 winner.

Montu provides paths to medical cannabis therapies through an integrated digital system.

"Montu [recorded] an extraordinary 20,728pc growth - the highest rate we've seen in a winner since 2004," Deloitte partner Josh Tanchel said.

Research could cut costs

Another cannabis industry leader, Cannatrek, placed sixth.

It's been busy focusing on R&D, collaborating with CSIRO on a study which has uncovered an environmentally friendly way to reduce cultivation costs, potentially leading to a reduction in costs for patients seeking medicinal cannabis treatment.

The six-month study focused on understanding the medicinal cannabis plant's demands for essential nutrients such as nitrogen, phosphorus and potassium.

Study results indicated that the application of potassium can be drastically reduced, by up to 50pc in specific growing environments, with minimal impact on crop development and yield, saving money and resource load, and reducing environmental impacts.

Cannatrek founder and CEO Tommy Huppert said research that improved manufacturing processes ultimately created higher quality medicinal cannabis, which was vital for Australia to compete in a global market.

"Until now, scientific literature around medicinal cannabis mineral nutrition has been sparse, and many other cultivators rely on nutrient recipes developed by fertiliser companies," Mr Huppert said.

"This can lead to over-fertilisation of the medicinal cannabis crop, which can produce environmentally damaging wastage. It also comes at a higher cost for the producer, which has a direct impact on patients."

Australia's medicinal cannabis industry is still young and has several challenges to face, including the lack of efficacy research, product affordability, and regulatory restrictions.

However, as more work is done, Queensland farmers have the potential to be leaders as the industry transitions from being a net importer and shores up domestic supply.

Subscribers have access to download our free app today from the App Store or Google Play

IN THE NEWS: