THE CRASH test dummies can take a much needed break with digital technologies taking their place.

Virtual reality and simulation are now key steps in the manufacturing of tractors and other machinery.

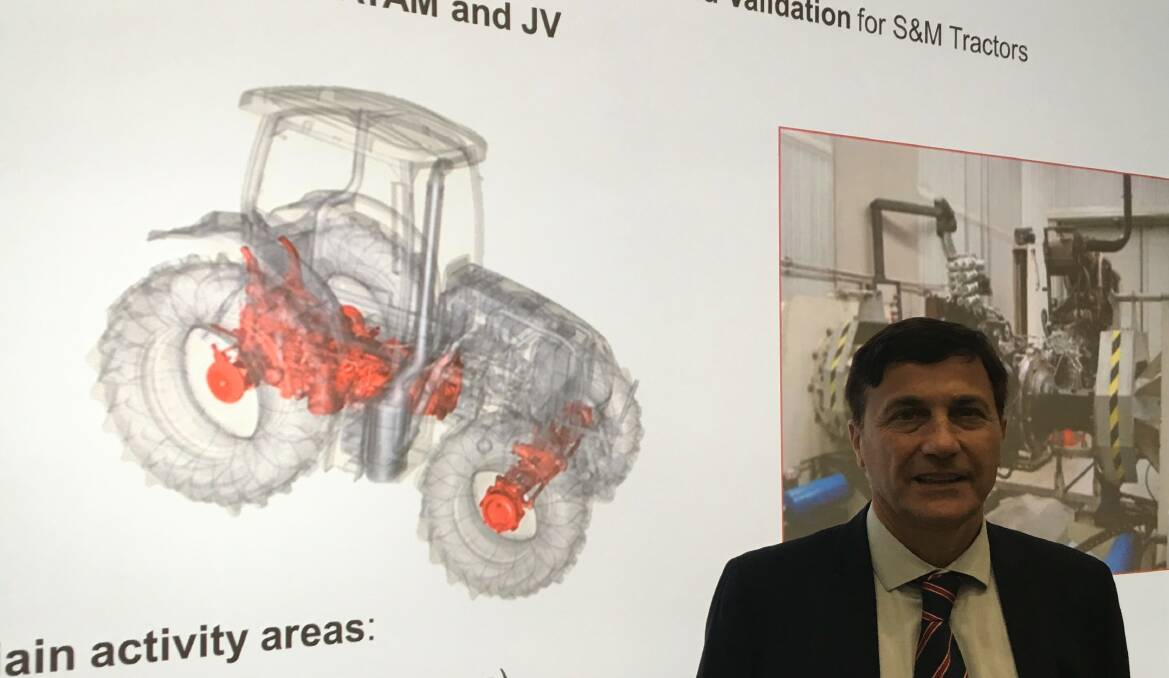

CNH Industrial dedicate a five hectare complex in Modena, Italy to simulation, design and prototype testing of their agricultural and industrial machinery, including tractors and headers.

CNH Industrial, global director of design analysis and simulation, Gennaro Monacelli said digital technologies were being used across the board in tractor design, in everything from safety, ergonomics and fuel consumption to crop and soil implement interactions.

“We live in the age of digital revolution,” he said.

“The new digital technologies will transform the way we think, the way we design and the way we produce our product.”

Mr Monacelli said digital technology allowed CNH to work internationally, collaborating on the early stages of development and engineering.

“This allows us to reduce the time to market and improve product performance,” he said.

This allowed the company to map out new agricultural machinery years before a standard prototype could be bought to market.

Mr Monacelli said of the over 900 employees based at the Modena site, about 57 percent were professional management and engineers.

“This technology requires new skills and new jobs,” he said.

Mr Monacelli said high performance computing (HPC) has reduced the requirement for crash test dummies and costly physical prototypes.

“We can evaluate the safety of our products and their structural integrity,” he said.

Mr Monacelli said thermal and aerodynamics of the machinery can be evaluated, giving the example of temperature simulations monitoring air-flow around a working tractor, which exceed measurements that could be made physically in the paddock.

This technology requires new skills and new jobs

- Gennaro Monacelli

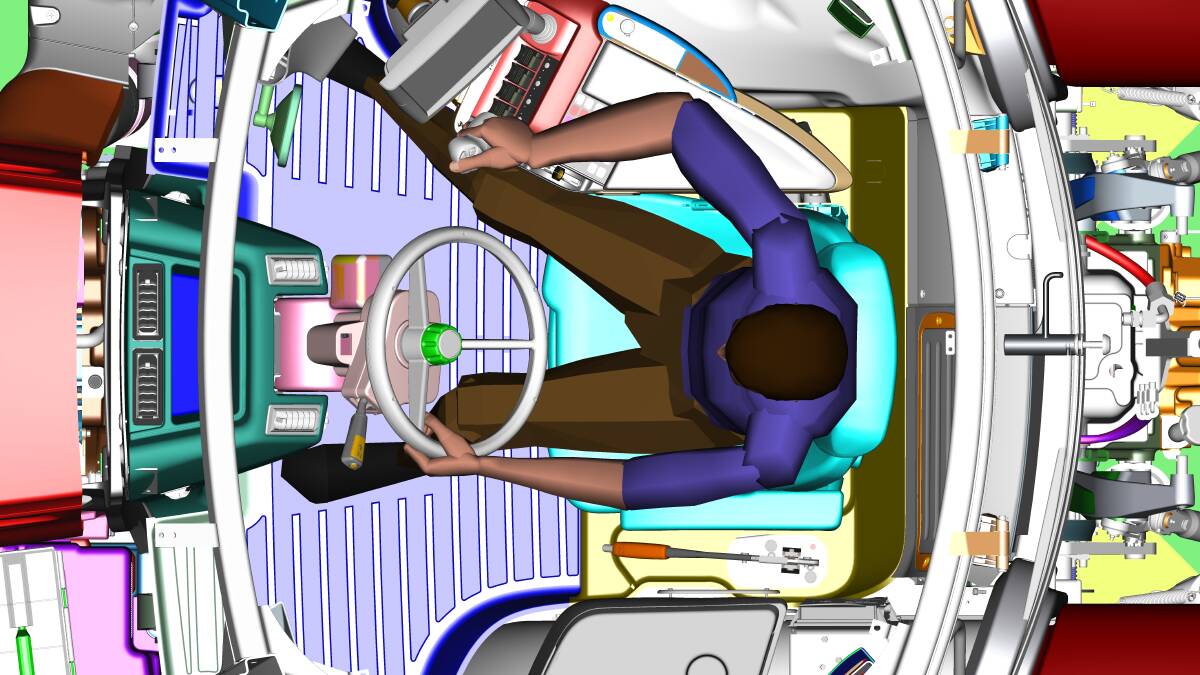

Tractor simulation allowed an infinite number of variables to be tested to both determine safety and comfort of hypothetical drivers, he said.

In a demonstration given to journalists visiting Modena, a simulated driver was used to see the effect during a tractor roll-over, checking the drivers head remained in the safety zone.

“In this way, with a simulation, you can see something that in the real world you cannot do,” Mr Monacelli said.

CNH Industrial is the parent company of agricultural machinery brands Case IH and New Holland, FTP Powertrain Technologies as well as trucking company Iveco.

- Sharon O’Keeffe visited CNH Industrial, Modena as a guest of FTP powertrain technologies.