BROTHERS Daniel and Josh Olsson say they are both "absolutely excited" to be delivering climate change solutions and helping to reduce poverty in one of South East Asia's poorest countries.

The brothers are heading to Laos later this month to manage AgCoTech's innovative new block making plant, which will manufacture molasses blocks containing technology that directly reduces methane emissions from cattle.

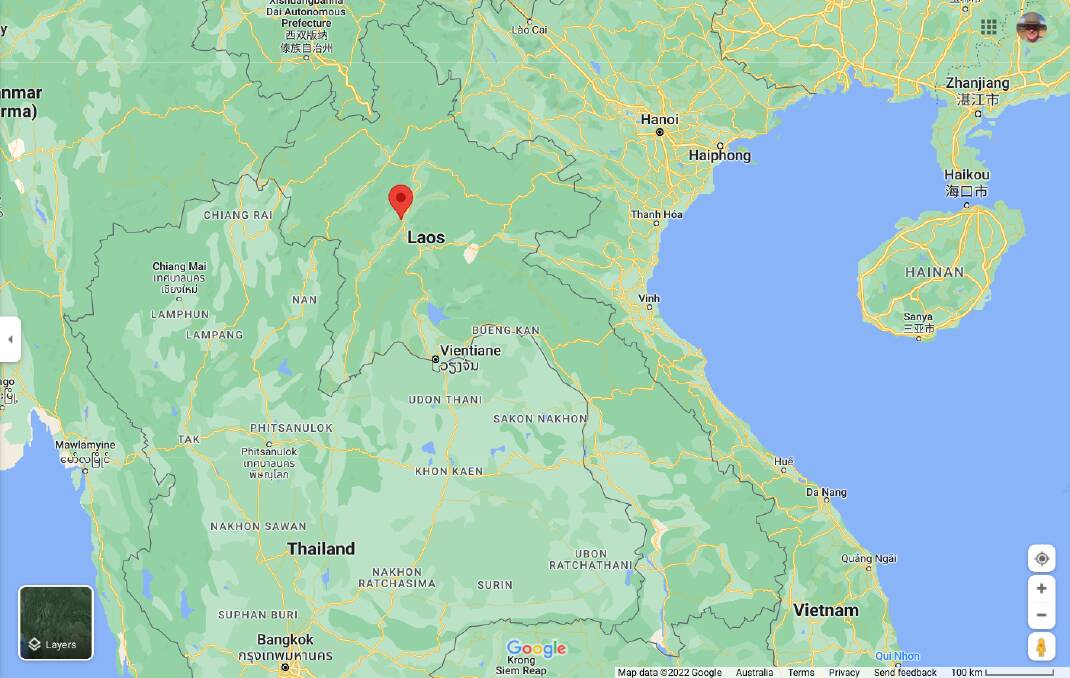

To be based in Luang Prabang in northern Laos, the brothers will help oversee the installation of the machinery and then work alongside local people to produce medicated molasses blocks.

The innovative green house gas reducing blocks, developed from research by the University of Sydney and supported by DFAT and Australia's Business Partnership Program, will then be distributed to local farmers and fed to the country's cattle and buffalo.

"It is absolutely a great thing to be doing," Daniel Olsson said.

"Climate change and poverty are two of the biggest challenges the world faces and through some clever, practical research this terrific solution has emerged.

"It is great knowing just how important the role agriculture has in making the world a better place."

Josh Olsson said he was also very keen to get to Laos.

"I don't doubt there will be plenty of challenges," he said.

"The first will be likely by installing the machinery and learning with the local people how to produce the best blocks possible in that environment.

"I am very sure we can make a big difference with these blocks once we get the factory up and smoothly running."

The medicated blocks were the result of research undertaken by Emeritus Professor Peter Windsor, who was able to show the specially formulated molasses blocks developed for livestock could both reduce smallholder farmer poverty and fight climate change.

In a nutshell, AgCoTech GHG blocks resulted in healthier, more fertile cows, which were more likely to have a calf on an annual basis. Those additional calves substantially increased the wealth of small holder farmers, helping lift them out of poverty.

In addition, the additional numbers of cattle and buffalo and extra income resulted in (particularly) women being able to move away from "sweat shop" jobs to take care of the increased numbers of livestock.

The mixing machinery is currently being trialled at AgCoTech's facility in Crestmead, south of Brisbane, where it is being put through its paces before being dismantled, cleaned and packed into the shipping container for export to Laos.

After it arrives in the land-locked South East Asian country, which shares borders with China, Myanmar, Thailand, Vietnam and Cambodia, it will be re-assembled and commissioned in a new, purpose built factory near Luang Prabang.

The mixing machine consists of two 5 tonne stainless steel mixing tanks, which are both powered by 10kW electric motors.

Designed and constructed by Oz-Tac Engineering in Gympie, the machinery was cleverly designed to be able to be packed in a 40-foot shipping container.

Ty Horne from Oz-Tac Engineering in Gympie said the machinery had also been designed to be as robust as possible.

"We've used all long-lasting materials to ensure plenty of years of reliable service with this equipment, even in the tropical conditions found in Laos," Mr Horne said.

"It's also built to Australian safety standards, so we're confident it will do the job very well."

Linked to the new Four Season methane mitigation enterprise AgCoTech Australia, the high speed mixing and pouring system ensures the actives used to suppress methane are homogenously dispersed within the blocks.

The technology essentially reduces methane by enabling an animal's rumen to operate more efficiently by increasing the digestibility of lower quality fibre commonly found throughout South East Asia during the extended dry season.

Instead of producing elevated amounts of methane, the bugs in the rumen are more efficiently able to convert the fibre into energy to produce more meat and milk and less methane.

Based on Prof Windsor's research, each 40kg block consumed reduces the equivalent of 800kg of annual CO2 equivalent production from cattle and buffalo in Laos.

Want daily news highlights delivered to your inbox? Sign up to the Queensland Country Life newsletter below.